Wisconsin-based Sadoff Iron & Metal Company has offered scrap metal recycling for more than 70 years. It collects non-ferrous metals and ferrous scrap, auto salvage, electronics recycling, and other materials at multiple sites in Wisconsin and Nebraska. Sadoff then provides ISO-certified recycled metal to steel mills and local foundries.

The company prides itself on its sustainable practices, but it has a costly challenge. When rainwater falls into the metal collection containers, it becomes contaminated by oils and other fluids on the metals. Sadoff pays by the gallon for the contaminated water to be hauled away and treated before being safely released into the environment.

Could there be a way to treat the water on site so it would be clean enough to meet sanitary requirements for discharging it into the city sewer system? In 2022, Sadoff teamed up with UW-Oshkosh faculty and students to research solutions.

“The collaboration between a local university and industry is an exciting adventure,” says Gary Griessmeyer, Sadoff’s environmental compliance manager. “We are in the scrap industry not chemistry or biology. Students help us learn while they learn.”

Pilot research to test solutions

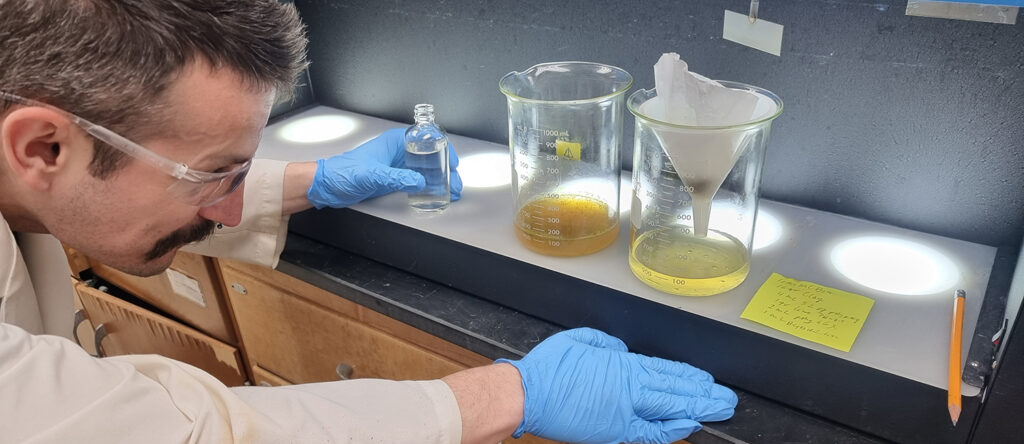

A grant from the Freshwater Collaborative of Wisconsin provided funding for Associate Professor Marcel Dijkstra to hire three undergraduate students to conduct pilot studies to test various processes of contaminant removal.

Dijkstra says the goal is to develop a cost-effective way to separate oil, cutting fluids and particulate matter containing heavy metals from the stormwater collected in scrap metal containers. This would allow Sadoff to clean the water on site – saving them money and reducing their carbon footprint while protecting the environment.

The Sadoff partnerships is one of the Water Technology Enterprise projects at UW-Oshkosh. These projects, funded through a larger Freshwater Collaborative grant, foster new research partnerships between the university’s Environmental Research and Innovation Center (ERIC) and external companies. Dijkstra notes that companies often don’t have the time or in-house expertise for smaller research projects. Having students work on them is cost effective and provides real-life experience to the students.

“This isn’t a class project,” he says. “It brings the educational component to a completely different level.”

Tyler Peskie, a UW-Oshkosh undergraduate, says working directly with an industry partner was an eye opener in terms of career possibilities. He graduates in May 2025 with a degree in environmental engineering technology.

“The first benefit of working on this experiment is that it gives me possible employment opportunities for more waste-related jobs,” he says. “Secondly, it benefited the university … it puts a lot more emphasis on research and application for industrial use.”

Tim Sommer, who graduated from UW-Oshkosh in December 2023, notes that many companies in the area work closely together, so experience working as a partner with a company can lead to further job opportunities. He secured a job as a consulting environmental scientist after graduation. Now he’s a corporate environmental engineer at Green Bay Packaging. He says having this project on his resume got his foot in the door.

“It is crucial to seek out experience outside of the classroom,” he says. “This is where many ‘soft skills’ are learned and many networking opportunities can be found.”

Creating ongoing partnerships

The students have finished the pilot research funded through the grant, and Dijkstra is continuing to work with Sadoff to refine the processes. He incorporates the project data into his classroom activities, and students enrolled in his class tour the Sadoff facility. The most recent tests are promising.

Griessmeyer is pleased with the progress and would encourage other business to partner with universities on research.

“When people think about water, they think about agriculture and phosphorus. They don’t think about other businesses that need help,” he says. “Even if we don’t get to the end game, I think it’s something that we really can put it in our quiver for now. And as technology gets better, we could pull it back out.”

Written by Heidi Jeter, Freshwater Collaborative

Link to original story: https://freshwater.wisconsin.edu/uwoshkosh-research-with-sadoff/