As electric vehicle batteries age out – typically after about 10 years – the world is bracing for a wave of expired lithium-ion batteries with no affordable way to recycle them. The problem is especially pressing with lithium iron phosphate batteries, the kind most commonly used in EVs, E-delivery vans and E-buses.

Traditional disposal of these batteries requires special handling that is costly. So is recovering material from lithium iron phosphate (LFP) batteries, which offers little value beyond lithium.

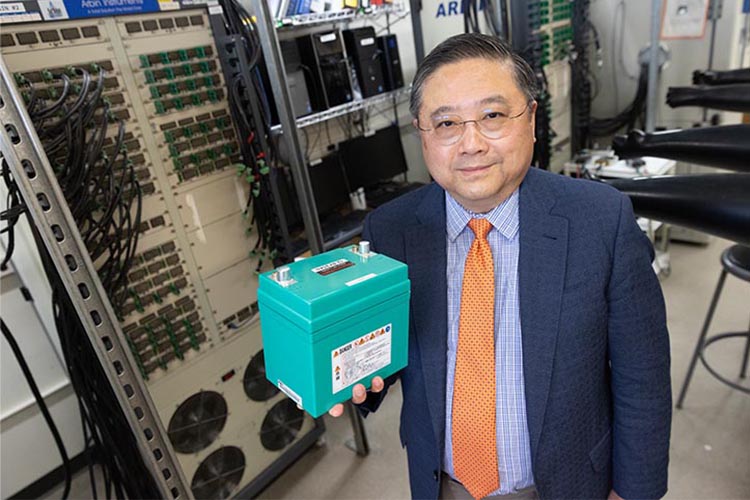

Deyang Qu, professor of mechanical engineering at UWM, has developed a strategy to transform a looming EV waste crisis into an environmental and economic opportunity: Turn retired LFP batteries into something the U.S. desperately needs – domestically produced fertilizer that reduces reliance on foreign imports.

lithium-ion battery electrode, with the intention of

separating the useful battery material from

the metal it’s attached to. The goal is to better

understand it and make it easier to recycle.

(UWM Photo/Troye Fox)

Using a well-established ion-exchange process, Qu and his team were the first to recover lithium from the LFP materials by replacing it with potassium. The remaining elements include phosphorus, potassium and nitrogen, which are key ingredients in fertilizer.

“Right now, it costs more to recycle the batteries than the value of what we recover,” Qu said. “But if we can turn those elements into fertilizer, we not only reduce waste but also support agriculture in Wisconsin and beyond.”

The proof of concept has been demonstrated with funding from a UWM internal Discovery and Innovation Grant and research partner, the USDA’s Agricultural Research Service.

Why fertilizer?

“There are only two options to deal with this kind of waste,” said Qu, a global leader in energy storage research. “Either the manufacturers or the government will have to pay to dispose of the waste. That’s what inspired us to look for an economically sustainable way.”

Fertilizers are a high-value product essential for increasing crop yields and maintaining food security.

Most of the mineral deposits needed to make fertilizers currently are imported, he said. Recycling these batteries would create a ready domestic supply of those ingredients. And the fertilizer could be produced with less energy because the raw materials don’t have to be mined or transported.

Taking the next step

The next steps are to manufacture the fertilizer at a larger scale in order to conduct comparative field tests against conventional fertilizers.

“Once we obtain support for the recycling-separation portion of the project, we will continue collaborating with the USDA to produce enough material for a one-acre tomato crop trial,” Qu said. “Those results will help us market this idea to major fertilizer companies.”

Wisconsin is well-positioned to lead this innovative, self-sustaining battery recycling effort, leveraging its strong manufacturing and agricultural base. The project promises to create high-tech jobs and provide workforce training in emerging green technologies.

Written by Laura Otto

Link to original story: https://uwm.edu/news/uwm-engineer-discovers-a-way-to-turn-used-ev-batteries-into-fertilizer/