Physics majors Marion Titze and Spencer Twining and Assistant Professor Ozgur Yavuzcetin peer at an evaporator in a physics lab in Upham Hall, on January 22, 2016. The equipment is used to make sensor patterns on silicon wafers, a process called shadow mask evaporation. Photo by Craig Schreiner.

Rob Olson smiles as he talks about how his company has changed since moving to the Innovation Center at Whitewater University Technology Park. The building, a business incubator on the city’s east side, is flush with entrepreneurs and startups. By design, it’s also keyed in to the University of Wisconsin-Whitewater and its faculty expertise.

And, as Olson appreciates, it’s a great source for new talent.

“When we relocated to the Innovation Center, we were excited about the opportunity to work with students, but couldn’t have imagined the depth and strength of our collaboration with the university,” he said.

The relationship between iButtonLink and students and faculty at UW-Whitewater has transformed the business and — in turn — has created invaluable experiences for students, who get to work at a face-paced, innovative technology company.

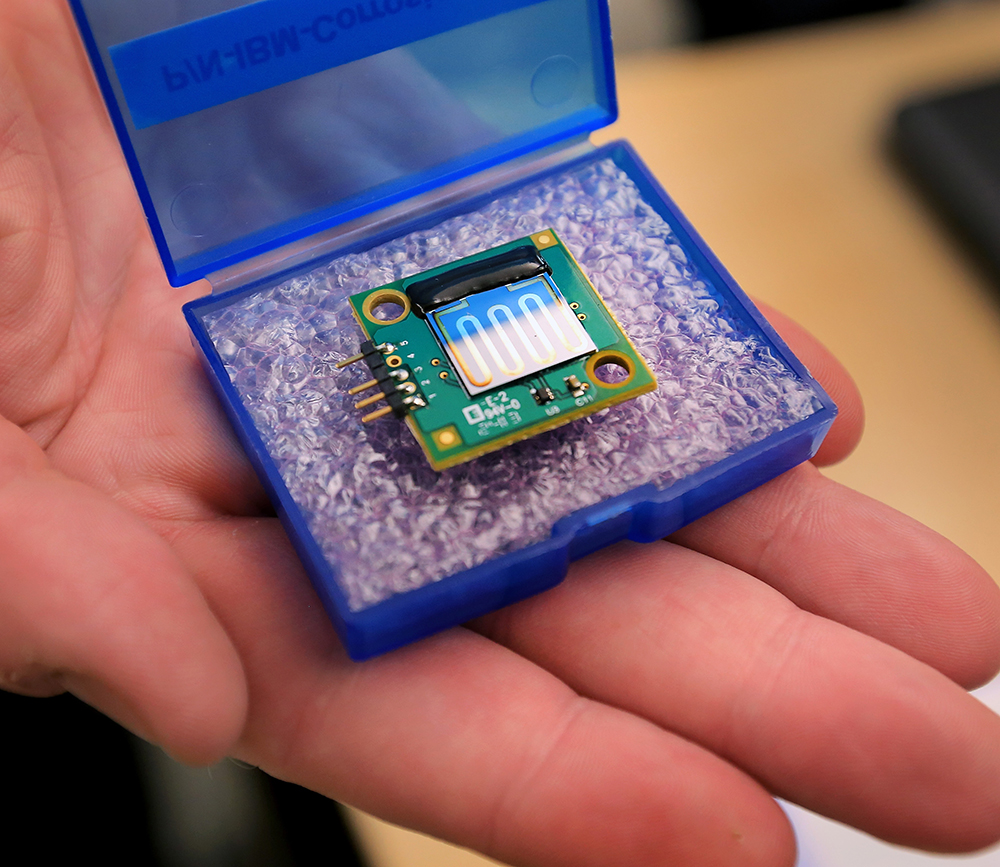

Founded in 2003, iButtonLink produces and distributes high-quality sensors and solutions that can be used for thousands of purposes, from food storage to field research. Products include temperature, humidity, voltage and light sensors, to name a few. The company serves clients ranging from Fortune 500 companies to small startups, and its products have been used in the harshest environments around the world, from the Arctic to the African savannah.

One of its customers, IBM, recently reported that iButtonLink’s products helped reduce energy use in its data centers by 53,400 megawatt hours — the equivalent of powering 5,000 U.S. homes.

Products by iButtonLink are on display during a tour on Thursday, September 10, 2015. Photo by Craig Schreiner.

What’s most exciting for UW-Whitewater students like Marion Titze is coming up with new solutions and products to meet clients’ needs.

“I was always interested in how things worked – from computers to subatomic particles to the human body,” she said. “Pair that with engineering and not only can I explain how things work, but I can build things to prove it.”

Titze, a nontraditional student from Broadhead, Wisconsin, joined iButtonLink as an intern in November 2014 and is engrossed in research and development. She and another student are working on calibration techniques and testing processes for corrosion sensors.

Ozgur Yavuzcetin, assistant professor of physics at UW-Whitewater, is their mentor on the project.

“We have shown that we can build and improve certain components of these sensors at the physics labs at UW-Whitewater, which saves the company time and money,” he said.

Physics majors Marion Titze and Spencer Twining and Assistant Professor Ozgur Yavuzcetin peer at an evaporator in a physics lab in Upham Hall, on January 22, 2016. The equipment is used to make sensor patterns on silicon wafers, a process called shadow mask evaporation. Photo by Craig Schreiner.

Through these collaborations, students see both research from a scientific and a business point of view. They learn to meet expectations and manage their time around sharp deadlines.

They’re also involved in many other facets of the company’s operations.

“One of our interns and did not even know how to open QuickBooks (accounting software) on his first day. He is now our dedicated lead in payroll,” Olson said. “Another student revamped many of our external documents that customers use including information sheets and user manuals. She also has swept our website and made the language we use more easily translatable for our many international customers.”

iButtonLink occupies five suites (4,063 sq. ft.) on the Innovation Center’s first floor, making it the largest private tenant in the building. With the exception of a few remote employees, 100 percent of the company’s operations — research and development, production, manufacturing, sales and marketing — happen in the Innovation Center. That it is truly a local business is a point of pride for Olson.

The region has taken notice as well. iButtonLink won the 2015 Innovation Business award from the Walworth County Economic Development Alliance.

For Titze, the ability to work both at a technology company and alongside her professors has been “amazing.”

“I have the best of both worlds here. I can apply what I learn in the classroom, as well as build real-world skills in the workforce. My mentors have pushed me far outside of my knowledge base comfort zone and I couldn’t be more thankful.”